Engine power plants run on the full range of fuel types, from different biofuels to all types of gases, such as sewage gas and biogas. They are therefore a very useful technology to help Europe reach net-zero emissions while making the best use of its resources.

Source: Kläranlage Weinheim

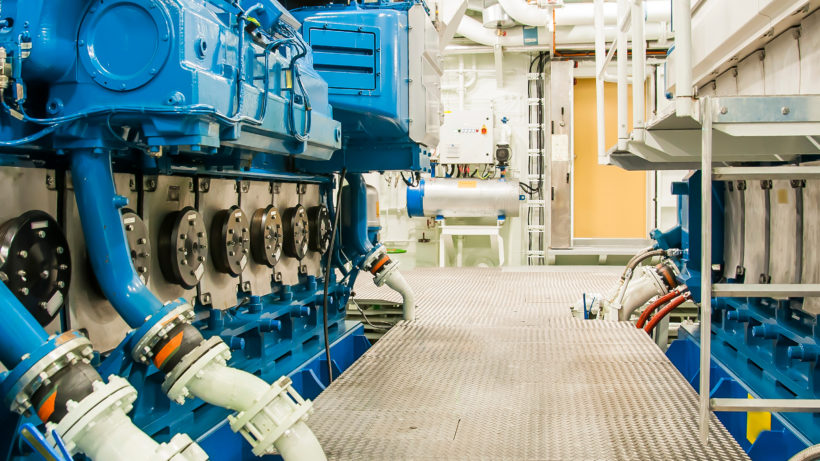

Weinheim Wastewater Treatment Plant

Every day, the Weinheim wastewater treatment plant cleans the wastewater from some 170,000 people in 7 municipalities in Southwest Germany. The plant’s fermentation tanks generate around 2,4 million m3 of fermentation gas per year. The gas is used to operate two cogeneration systems, that provide electricity and heat, covering and even exceeding the plant’s annual energy consumption.

From food farmer to energy farmer

“Everything’s good for something.” That’s the philosophy of Matthias Preußner, who leads the Energor company and is its public face. Energor is based in Friedberg in Hessen to the north of Frankfurt (Germany) – and its business is simply to use food waste to generate heat and electrical power. For the past 20 years, it has been doing so using engine-based combined-heat-and-power (CHP) plants.

Reliable and green energy for airports

Memmingen Airport is Bavaria’s third commercial airport. The Airport’s heating and power needs are met by a flexible combined-heat-and-power plant, powered by locally-sourced biogas. The plant only runs when not engouh weather-dependent electricity is available – securing the airport’s energy supply and supporting its goal of achieving net-zero CO2 emissions by 2030. The plant also supplies climate-friendly district heating to the neighboring industrial and commercial operations.

Source: Caterpillar Energy Solutions GmbH

Bioenergie Fargau GmbH & Co

When, in 2010, milk prices were under pressure, this farmer in the North of Germany decided to install a biogas plant. With its 265 ha of land and 200 dairy cows, the farm uses liquid manure and energy crops to produce 3.7 million kWh electricity and a 3 million kWh heat a year.

While the electricity is injected into the grid, the heat is used to dry the digestion residue produced by the system, which in turn is used to produce a high-grade and sterile bedding material for the cow barn.