Very often, engine power plants run as “cogeneration” plants, providing both electricity and heat. Cogeneration plants are an attractive solution for industry, local public buildings and district heating systems.

Source: EC Power

Baekke School

Baekke School is a municipal school in Denmark. It has approx. 280 students and consumes 130 MWh electricity and 430 MWh of heat a year. To reduce its energy consumption, the school replaced a gas boiler with a mini-CHP unit, combined with a heat pump. The school to reduce its energy bill by 23% and its annual carbon emissions by a third.

Source: EC Power

Ollerup Gymnastics Academy

The Ollerup Gymnastics Academy in Denmark offers its 240 residential students a wide variety of sports courses. The campus comprises two swimming pools and five gyms - one of them for up to 3,000 spectators. The installation consumes 550 kWh of electricity and 2,400 kWh of heat a year.

The motto of the 100-year-old educational facility is to “create a better future”. In 2018, this principle was given some new energy - the old 700 kW boiler and the 60 kW CHP were replaced with a modern energy centre consisting of four mini-CHP units, two 50 kW heat pumps, a new 975 KW condensing gas boiler, and four 1,000 litre storage tanks.

Apart from heat, the four m-CHP units provide 73% of the campus’ power consumption, including electricity for the two heat pumps. Thanks to this solution, the academy’s energy bill dropped by 28 % and its carbon emissions by over a third.

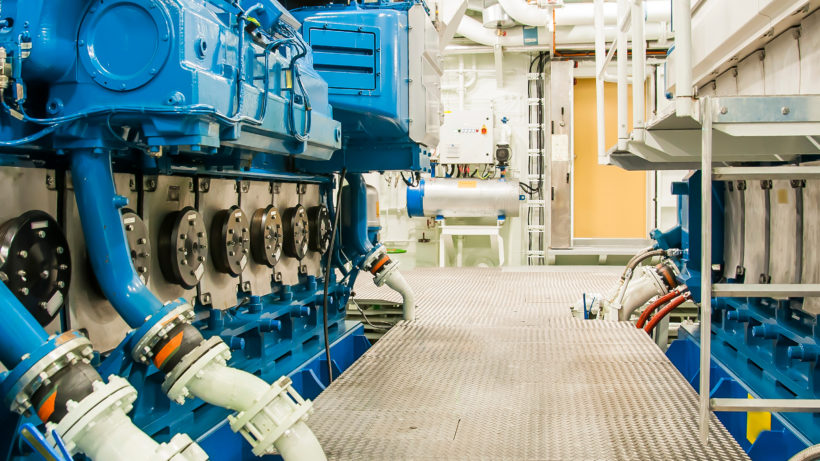

Source: Wärtsilä

Heating, Cooling and Electricity for Linate Airport

Milan Linate is Italy’s fifth largest airport. Terminal buildings have huge power and thermal energy needs. Therefore, the airport has chosen a “trigeneration” plant to provide heating, cooling and electricity supply. The trigeneration plant works with three gas engines.

The plant is designed to meet the variations in heating and cooling demand in summer and winter. In winter, it provides 82 MWth of heat and, in summer, 72 MWth of cool air. The electricity produced is fed back into the grid – except in the event of a break in the grid supply.

Source: Stadtwerke Lübeck

The Lübeck “Energy Bunker”

The municipal utility Stadtwerke Lübeck in the North of Germany runs 14 cogeneration plants to provide electricity and heat to the inhabitants of this UNESCO World Heritage city. One of those plants is located in a former bunker from 1941 in the borough of St. Lorenz-Süd, uniting historical remembrance with top-notch technology.

Source: Unilever

Heat & Power for Cost-Efficient Ice-Cream Production

Germany’s largest ice cream producer has installed a heat-controlled cogeneration unit at its plant of Heppenheim. The heat is not only used to turn the basic ingredients (milk sugar, fat, chocolate, fruit preparations, aromas, water and air) into delicious ice cream but also in the cleaning and heating circuits and for the supply of hot water.