Hydrogen-Ready Engine Power Plants

A common definition of H2-readiness

The decarbonisation of Europe’s power generation requires dispatchable, flexible but also climate-neutral gas power plants to complement the variable generation from wind and sun. At the same time the gas sector decarbonises, especially by introducing hydrogen.

It is important that gas power plants are able to operate with these decarbonised gases and thus can provide climate-neutral energy. Outlining the H2-readiness of future engine power plants will ensure that investments are future-proof and do not lead to a carbon lock-in.

Already today most power plants are capable of handling a certain share of hydrogen blended into natural gas. Now the power plant industry optimises the technology to the use of hydrogen.

The purpose of this paper is to provide a common understanding of H2-readiness for engine power plants. The European engine power plant industry will voluntarily indicate with each newly built power plant the specific category of H2-readiness defined by:

- Percentage share of hydrogen[i]

- Technical adaptions needed to reach the desired H2-readiness level in the future

Percentage-share of hydrogen

Hydrogen will remain a scarce resource over the next decade. It is likely that a limited number of hydrogen valleys and a backbone grid connecting these valleys and large-scale generation facilities will be built in Europe within the near future. These regions and hydrogen pipelines will be extended in the future. In the remaining gas grid, especially the distribution grid, the blending of certain levels of hydrogen into the natural gas pipeline will be a valuable option during the transition. The maximum blending share is expected to remain limited to around 25% – above that level there will most likely be a switch to pure hydrogen in one step. By 2050, that switch should be fully concluded.

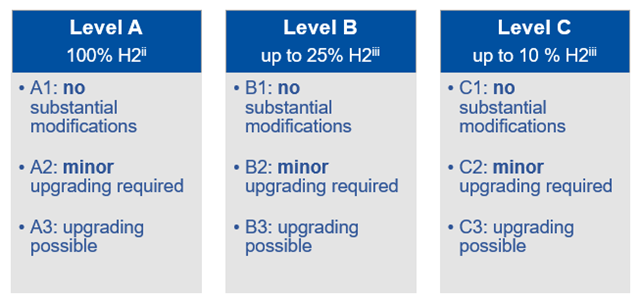

Considering this context, the European engine power plant industry defines hydrogen-readiness in 3 levels according to the hydrogen contenti of the gas used:

- Hydrogen-Ready Level A: 100% hydrogen[ii]

- Hydrogen-Ready Level B: up to 25% hydrogen blended into natural gas[iii]

- Hydrogen-Ready Level C: up to 10% hydrogen blended into natural gasiii

Technical adaptations

Today’s new power plants will typically start operating with natural gas for a number of years. However, a new power plant can already be designed and built to be H2-ready. This allows operators to easily upgrade the plant for the specific hydrogen content available in the gas grids.

The efforts to upgrade these power plants may vary for each power plant, as they are built according to specific requirements agreed between the plant operators and the technology providers.[iv]

The European power plant industry defines sub-categories for each H2-readiness level:

- Category 1: No substantial modifications

No substantial modification of the power plant’s hardware is necessary to reach the relevant H2-readiness level. However, the plant may require adaptations in operation, service & maintenance, operating procedures, software etc.

Modifications are estimated by the technology supplier to be up to 5% of the overall costs of building a new power plant. Also, there may be modifications necessary in the gas supply outside the plant.

- Category 2: Minor upgrading necessary

The plant is technically suitable and retrofittable to operate with the hydrogen share of the category. Certain modifications of the hardware, software, etc. will be required before being able to operate. Many of the upgrading efforts can be done as part of regular inspection and maintenance activities.

The technology suppliers estimate the costs for this upgrade to be up to 10% of the overall cost of building this power plant[v].

- Category 3: Upgrading technically and economically possible

The plant is technically suitable and retrofittable to operate with the hydrogen share of the category. Certain modifications of the hardware, software etc will be required before being able to practically operate with the mentioned hydrogen level.

The technology suppliers estimate the costs for this upgrade to be up to 30% of the overall cost of building this power plant.

Published in August 2021 by EUGINE

[i] % figures relating to the volume share of hydrogen blended into natural gas.

[ii] This is a non-technical wording. As there are often fractions of other gases in the pipeline system, the technically more correct term would be hydrogen content >95%

[iii] Depending on the specific composition of the base gas

[iv] The technical capability of a plant to handle hydrogen may in some cases be higher than the contractually agreed capability

[v] Costs relating to the inflation-adjusted costs of building the original plant. Subject to review when significant parameters change.